Better Farming

February 2017

Dig Deeper:

BetterFarming.com29

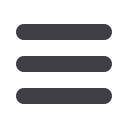

Mark checks the status of the automated control system in the anteroom to the barn. The LCD

display shows the projected growth curve of chicks over their 32-day stay leading up to market.

The same readout is available on his smartphone and computers. The system sends alerts to

farmers if there is a disruption to food supplies or water pressure, or if the barn’s temperature or

humidity reach critical levels.

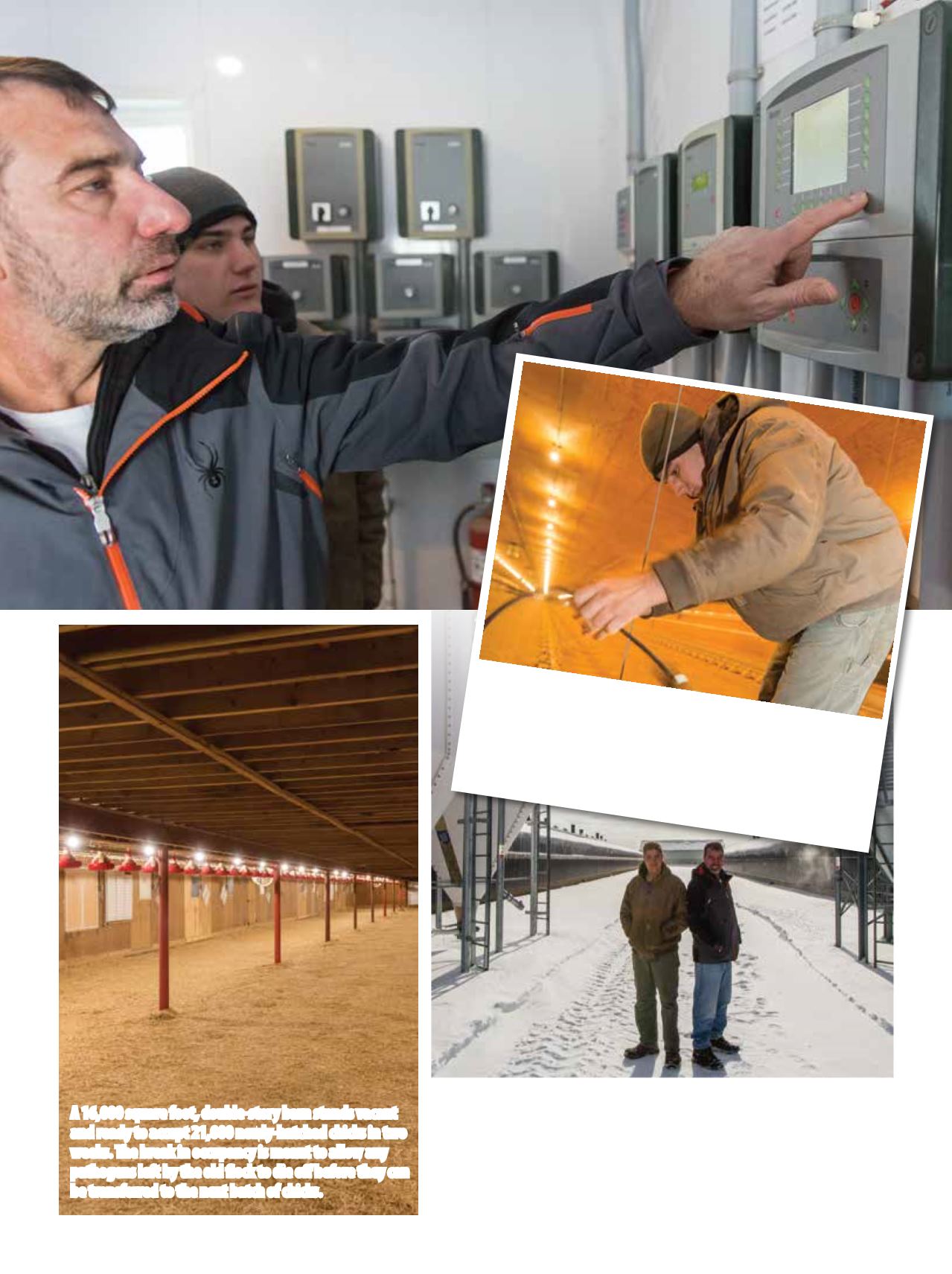

A 16,000 square foot, double-story barn stands vacant

and ready to accept 21,000 newly-hatched chicks in two

weeks. The break in occupancy is meant to allow any

pathogens left by the old flock to die off before they can

be transferred to the next batch of chicks.

20-year-old Jonathan Hermann, left, and his father, Mark, stand between

two poultry barns on their second property in Cambridge. Jonathan has just

completed an associate diploma in agriculture at the Ridgetown campus of

the University of Guelph and will work on the family farm full-time. He also

plans to study for his Class AZ driving licence which will allow him to take on

an even greater role in the family business.

Jonathan checks the automated feeder system in a freshly set-up

barn. In addition to dispensing measured amounts of food, the line

is attached to a winch system that automatically lifts feeders to

match the height of birds as they grow. The assembly can also be

raised to the ceiling so that it is out of the way when cleaning the

barn floor.