20

Farm News First >

BetterFarming.com

Better Farming

August 2016

Like many other farmers with

anaerobic digesters in Ontario, Korb

Whale soon ran into challenges when

he built one in 2010.

From sourcing off-farm organics to

keep the facility running to quirks

and problems with equipment, the

struggles led Whale to call a meeting

with other digester operators.

“Everybody held their cards pretty

close to their chest,” he recalls.

“Because it’s a competitive market

and we weren’t sure who each other

was. And little by little we realized

that we all were going through

similar things and we might as well

learn from each other’s mistakes.

And (by) about the second or third

meeting we all realized we were

sourcing off-farm waste with varying

degrees of success and none of us

had a very solid background in the

waste sector.”

The group realized something

MAIN

FEATURE

Company manages digesters’ craving for organic waste

else: by working together, they could

offer waste operators a regular place

for organic waste with several

drop-off points.

Three years ago, 12 of these

digester operators – 10 of whom are

farmers – would go on to establish

Cornerstone Renewables Inc., a

company to source organic waste for

the member digesters.

Today, the group accepts nearly

17,000 tonnes a month of organic

waste, more than triple the 5,200

tonnes operators accepted when they

first joined forces, and they have the

capacity to handle 220,000 tonnes

annually. At commercial sites such

as Seacliffe Energy Ltd. in

Leamington and Woolwich Bio-En in

Elmira, there also exists the capacity

to process commercial or dirty waste,

such as packaging mixed in with

organic waste and a form of treated

wastewater from meat processors

that contains fats, oils and grease.

“That means we’re able to offer a

very robust solution to all kinds of

different waste producers,” says

Travis Woollings, Cornerstone’s

general manager.

Despite Ontario’s recent an-

nouncement of funds to kick-start

the renewable natural gas industry,

building more sites is not a priority

for Cornerstone.

Instead, on the company’s wish

list is establishing an organic

transfer facility, possibly in the

Greater Toronto Area, that could

“depackage” waste and “bulk it up”

to send to other locations.

There’s a lot of volume in the GTA

but it comes in small packages,

Woollings explains. “It doesn’t make

economic sense to ship that small

volume long distances.”

Sourcing organics won’t be a

challenge for the anaerobic digester

that will eventually supply Rural Green

Energy with renewable natural gas.

The digester, which will be built at a

beef operation owned by John Yssel-

stein Jr. in Oxford County, will supple-

ment manure with vegetable waste.

John Ysselstein Sr. says that the

family currently buys or acquires

vegetable waste from local sources,

such as food processor Bonduelle

Canada. They feed it to their ani-

mals, and it can also be used in the

digester, he says.

Jennifer Green, executive director

of the Canadian Biogas Association,

says the organization wants the

Ontario Ministry of the Environment

and Climate Change to prioritize

organics diversion to ensure a steady

supply of organics for anaerobic

digesters. “To be able to create

conditions where the use and

optimization of those organic materi-

als is prioritized is important,” she

says. “Those things have to come

hand-in-hand. The Climate Action

Plan, the Organic Action Plan that

will unfold from the Waste-Free

Ontario Act, all of those will have to

play together, as well as the long-

term energy plan that the province

will be unveiling in the fall.”

BF

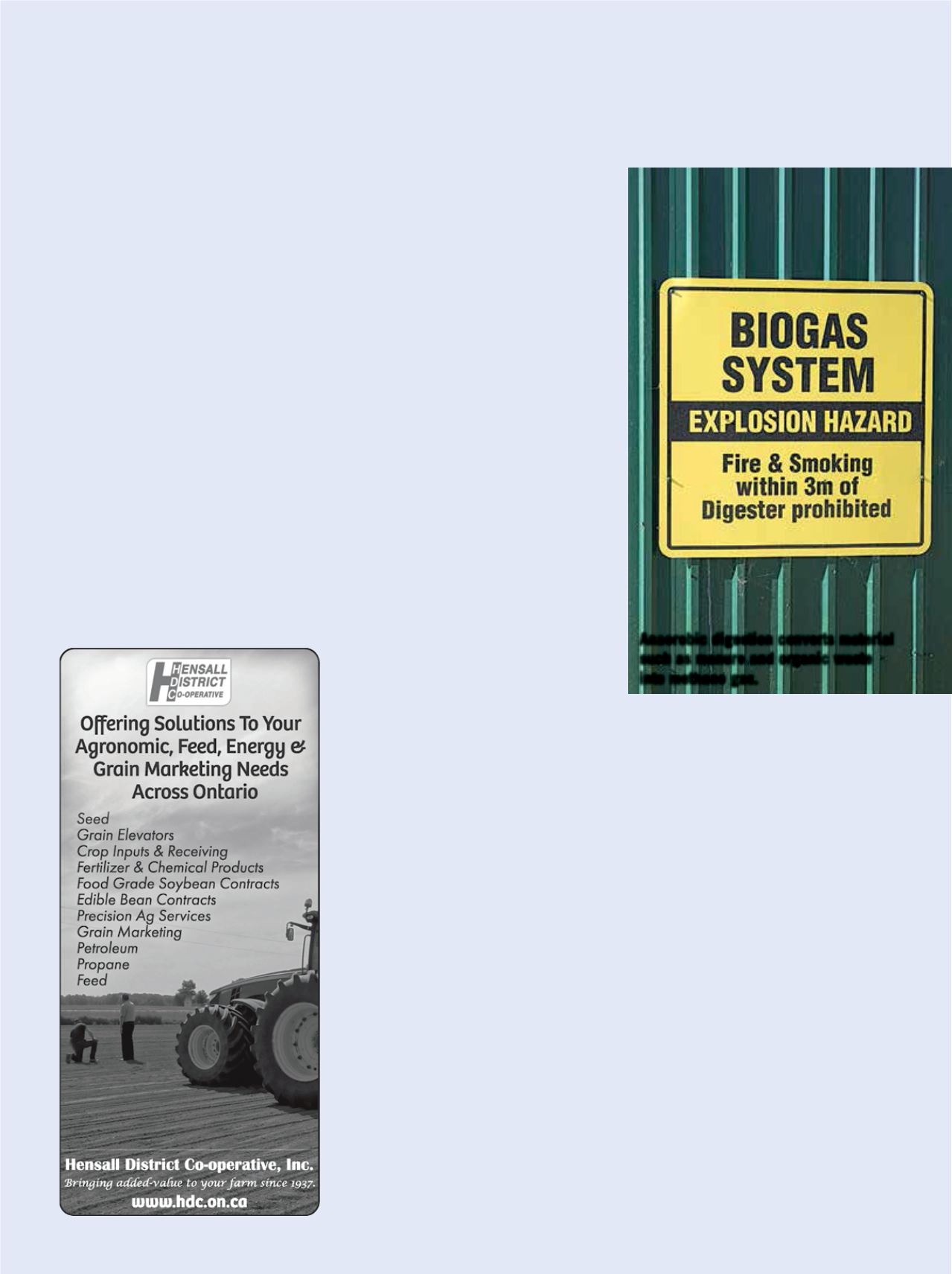

Anaerobic digestion converts material

such as manure and organic waste

into methane gas.

20

Farm News First >

BetterFarming.com

Better Farming

August 2016

Like many other farmers with

anaerobic digesters in Ontario, Korb

Whale soon ran into challenges when

he built one in 2010.

From sourcing off-farm organics to

keep the facility running to quirks

and problems with equipment, the

struggles led Whale to call a meeting

with other digester operators.

“Everybody held their cards pretty

close to their chest,” he recalls.

“Because it’s a competitive market

and we weren’t sure who each other

was. And little by little we realized

that we all were going through

similar things and we might as well

learn from each other’s mistakes.

And (by) about the second or third

meeting we all realized we were

sourcing off-farm waste with varying

degrees of success and none of us

had a very solid background in the

waste sector.”

The group realized something

MAIN

FEATURE

Company manages digesters’ craving for organic waste

else: by working together, they could

offer waste operators a regular place

for organic waste with several

drop-off points.

Three years ago, 12 of these

digester operators – 10 of whom are

farmers – would go on to establish

Cornerstone Renewables Inc., a

company to source organic waste for

the member digesters.

Today, the group accepts nearly

17,000 tonnes a month of organic

waste, more than triple the 5,200

tonnes operators accepted when they

first joined forces, and they have the

capacity to handle 220,000 tonnes

annually. At commercial sites such

as Seacliffe Energy Ltd. in

Leamington and Woolwich Bio-En in

Elmira, there also exists the capacity

to process commercial or dirty waste,

such as packaging mixed in with

organic waste and a form of treated

wastewater from meat processors

that contains fats, oils and grease.

“That means we’re able to offer a

very robust solution to all kinds of

different waste producers,” says

Travis Woollings, Cornerstone’s

general manager.

Despite Ontario’s recent an-

nouncement of funds to kick-start

the renewable natural gas industry,

building more sites is not a priority

for Cornerstone.

Instead, on the company’s wish

list is establishing an organic

transfer facility, possibly in the

Greater Toronto Area, that could

“depackage” waste and “bulk it up”

to send to other locations.

There’s a lot of volume in the GTA

but it comes in small packages,

Woollings explains. “It doesn’t make

economic sense to ship that small

volume long distances.”

Sourcing organics won’t be a

challenge for the anaerobic digester

that will eventually supply Rural Green

Energy with renewable natural gas.

The digester, which will be built at a

beef operation owned by John Yssel-

stein Jr. in Oxford County, will supple-

ment manure with vegetable waste.

John Ysselstein Sr. says that the

family currently buys or acquires

vegetable waste from local sources,

such as food processor Bonduelle

Canada. They feed it to their ani-

mals, and it can also be used in the

digester, he says.

Jennifer Green, executive director

of the Canadian Biogas Association,

says the organization wants the

Ontario Ministry of the Environment

and Climate Change to prioritize

organics diversion to ensure a steady

supply of organics for anaerobic

digesters. “To be able to create

conditions where the use and

optimization of those organic materi-

als is prioritized is important,” she

says. “Those things have to come

hand-in-hand. The Climate Action

Plan, the Organic Action Plan that

will unfold from the Waste-Free

Ontario Act, all of those will have to

play together, as well as the long-

term energy plan that the province

will be unveiling in the fall.”

BF

Anaerobic digestion converts material

such as manure and organic waste

into methane gas.

20

Farm News First >

BetterFarming.com

Better Farming

August 2016

Like many other farmers with

anaerobic digesters in Ontario, Korb

Whale soon ran into challenges when

he built one in 2010.

From sourcing off-farm organics to

keep the facility running to quirks

and problems with equipment, the

struggles led Whale to call a meeting

with other digester operators.

“Everybody held their cards pretty

close to their chest,” he recalls.

“Because it’s a competitive market

and we weren’t sure who each other

was. And little by little we realized

that we all were going through

similar things and we might as well

learn from each other’s mistakes.

And (by) about the second or third

meeting we all realized we were

sourcing off-farm waste with varying

degrees of success and none of us

had a very solid background in the

waste sector.”

The group realized something

MAIN

FEATURE

Company manages digesters’ craving for organic waste

else: by working together, they could

offer waste operators a regular place

for organic waste with several

drop-off points.

Three years ago, 12 of these

digester operators – 10 of whom are

farmers – would go on to establish

Cornerstone Renewables Inc., a

company to source organic waste for

the member digesters.

Today, the group accepts nearly

17,000 tonnes a month of organic

waste, more than triple the 5,200

tonnes operators accepted when they

first joined forces, and they have the

capacity to handle 220,000 tonnes

annually. At commercial sites such

as Seacliffe Energy Ltd. in

Leamington and Woolwich Bio-En in

Elmira, there also exists the capacity

to process commercial or dirty waste,

such as packaging mixed in with

organic waste and a form of treated

wastewater from meat processors

that contains fats, oils and grease.

“That means we’re able to offer a

very robust solution to all kinds of

different waste producers,” says

Travis Woollings, Cornerstone’s

general manager.

Despite Ontario’s recent an-

nouncement of funds to kick-start

the renewable natural gas industry,

building more sites is not a priority

for Cornerstone.

Instead, on the company’s wish

list is establishing an organic

transfer facility, possibly in the

Greater Toronto Area, that could

“depackage” waste and “bulk it up”

to send to other locations.

There’s a lot of volume in the GTA

but it comes in small packages,

Woollings explains. “It doesn’t make

economic sense to ship that small

volume long distances.”

Sourcing organics won’t be a

challenge for the anaerobic digester

that will eventually supply Rural Green

Energy with renewable natural gas.

The digester, which will be built at a

beef operation owned by John Yssel-

stein Jr. in Oxford County, will supple-

ment manure with vegetable waste.

John Ysselstein Sr. says that the

family currently buys or acquires

vegetable waste from local sources,

such as food processor Bonduelle

Canada. They feed it to their ani-

mals, and it can also be used in the

digester, he says.

Jennifer Green, executive director

of the Canadian Biogas Association,

says the organization wants the

Ontario Ministry of the Environment

and Climate Change to prioritize

organics diversion to ensure a steady

supply of organics for anaerobic

digesters. “To be able to create

conditions where the use and

optimization of those organic materi-

als is prioritized is important,” she

says. “Those things have to come

hand-in-hand. The Climate Action

Plan, the Organic Action Plan that

will unfold from the Waste-Free

Ontario Act, all of those will have to

play together, as well as the long-

term energy plan that the province

will be unveiling in the fall.”

BF

Anaerobic digestion converts material

such as manure and organic waste

into methane gas.

20

Farm News First >

BetterFarming.com

Better Farming

August 2016

Like many other farmers with

anaerobic digesters in Ontario, Korb

Whale soon ran into challenges when

he built one in 2010.

From sourcing off-farm organics to

keep the facility running to quirks

and problems with equipment, the

struggles led Whale to call a meeting

with other digester operators.

“Everybody held their cards pretty

close to their chest,” he recalls.

“Because it’s a competitive market

and we weren’t sure who each other

was. And little by little we realized

that we all were going through

similar things and we might as well

learn from each other’s mistakes.

And (by) about the second or third

meeting we all realized we were

sourcing off-farm waste with varying

degrees of success and none of us

had a very solid background in the

waste sector.”

The group realized something

MAIN

FEATURE

Company manages digesters’ craving for organic waste

else: by working together, they could

offer waste operators a regular place

for organic waste with several

drop-off points.

Three years ago, 12 of these

digester operators – 10 of whom are

farmers – would go on to establish

Cornerstone Renewables Inc., a

company to source organic waste for

the member digesters.

Today, the group accepts nearly

17,000 tonnes a month of organic

waste, more than triple the 5,200

tonnes operators accepted when they

first joined forces, and they have the

capacity to handle 220,000 tonnes

annually. At commercial sites such

as Seacliffe Energy Ltd. in

Leamington and Woolwich Bio-En in

Elmira, there also exists the capacity

to process commercial or dirty waste,

such as packaging mixed in with

organic waste and a form of treated

wastewater from meat processors

that contains fats, oils and grease.

“That means we’re able to offer a

very robust solution to all kinds of

different waste producers,” says

Travis Woollings, Cornerstone’s

general manager.

Despite Ontario’s recent an-

nouncement of funds to kick-start

the renewable natural gas industry,

building more sites is not a priority

for Cornerstone.

Instead, on the company’s wish

list is establishing an organic

transfer facility, possibly in the

Greater Toronto Area, that could

“depackage” waste and “bulk it up”

to send to other locations.

There’s a lot of volume in the GTA

but it comes in small packages,

Woollings explains. “It doesn’t make

economic sense to ship that small

volume long distances.”

Sourcing organics won’t be a

challenge for the anaerobic digester

that will eventually supply Rural Green

Energy with renewable natural gas.

The digester, which will be built at a

beef operation owned by John Yssel-

stein Jr. in Oxford County, will supple-

ment manure with vegetable waste.

John Ysselstein Sr. says that the

family currently buys or acquires

vegetable waste from local sources,

such as food processor Bonduelle

Canada. They feed it to their ani-

mals, and it can also be used in the

digester, he says.

Jennifer Green, executive director

of the Canadian Biogas Association,

says the organization wants the

Ontario Ministry of the Environment

and Climate Change to prioritize

organics diversion to ensure a steady

supply of organics for anaerobic

digesters. “To be able to create

conditions where the use and

optimization of those organic materi-

als is prioritized is important,” she

says. “Those things have to come

hand-in-hand. The Climate Action

Plan, the Organic Action Plan that

will unfold from the Waste-Free

Ontario Act, all of those will have to

play together, as well as the long-

term energy plan that the province

will be unveiling in the fall.”

BF

Anaerobic digestion converts material

such as manure and organic waste

into methane gas.