24

Farm News First >

BetterFarming.comBetter Farming

August 2016

FIELD

TRIP

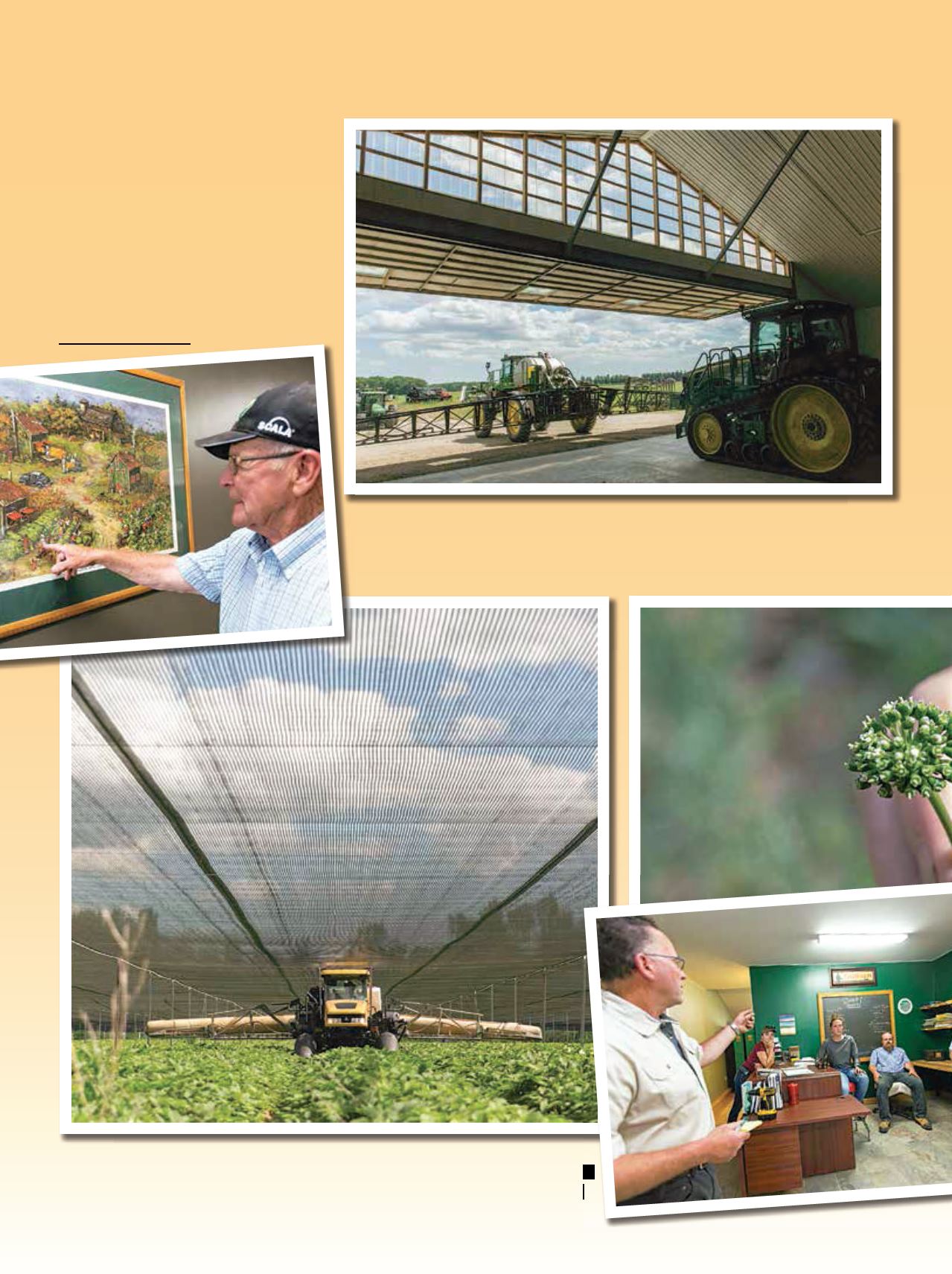

A 60-foot hydraulic door stands open at the Chesney workshop, which was built

in 2014 to custom specifications set out by the family. The 20,000 square foot

facility, which houses the workshop, company offices, a meeting room and a

presentation area, is the nerve centre of the operation.

A sprayer applies a preventative fungicide as part of an integrated pest

management system. The crop is relatively difficult to grow, requiring three to

four years before the first harvest, and a minimum of 70 per cent shade. The

plant is also sensitive to extremes in heat and moisture.

Bill Sr. points out the different jobs

illustrated in a print by Irene Anderson

titled “Tobacco Harvest in the Old

Days,” (circa 1940s) hanging on their

office wall. The elder Chesney started

working on the family’s tobacco

operation in 1942 at the age of seven.

His job back then was to ride the horse

that would pull a “boat” of tobacco

leaves as other workers harvested the

crop. The farm continued producing

tobacco until 1995.

Bill Sr. holds a ginseng flower,

which is pulled by hand at this

stage of development. This stops

the plant from directing energy

into seed creation and in turn

can increase root size by up

to 30 per cent.