28

Better pork

August 2016

FEATURE

“The system sees each sow allocated

an individual LISA2 logger when

penned for farrowing,” he explains.

“The sow herd number is scanned

from a transponder or punched in.”

Time and date of first attendance is

automatically logged, as is the sow’s

medical history and treatments,

these details coming automatically

from the herd computer. When far-

rowing starts, the stockperson taps

in details of (piglets) born alive and

dead. During farrowing, the indi-

vidual LISA2 data loggers are hung

on special hooks above each farrow-

ing pen. Pre-set surveillance intervals

during farrowing are fed in from

the herd computer, and the LISA2

features an acoustic/visual alarm to

remind the attendant. If an alarm

is ignored or tampered with, this is

also noted by the herd computer.

The LISA2 data loggers will sell in

Europe in batches of 10 at a total

price equivalent to C $3,770.

Time-out for the heaviest sucklers

A new timed-lock system that keeps

the heaviest newborn piglets away

from Mum’s milk to give a better

chance to weaker piglets is prov-

ing a litter lifesaver in Danish trials.

Another brainwave from the innova-

tive Danish engineer Niels Veng and

his team at Farm Innovation, the

so-called VE 925 Split Suckling Aid,

is designed to allow the firstborn a

good drink of colostrum after which

they can be locked away for a pe-

riod, allowing weaker piglets free ac-

cess to the udder. The Split Suckling

Aid takes the form of an enclosed

creep area (usually where the piglets

sleep between suckling bouts). There

is a solid fibreglass barrier in front of

this enclosed creep area and this bar-

rier has a small door in it. The door

can be kept closed with a time-lock.

Inventor Niels Veng says the proce-

dure of locking up the heavier litter

members after they have had a drink

might have to be carried out several

times during the first day with litters

that are particularly big or non-uni-

form. “Current breeding successes

are giving us viable litters often top-

ping 14 live piglets. Making sure that

all litter members get that important

first few drinks of colostrum makes

all the difference to piglet survival,

and therefore breeding herd profit at

the end of the day.”

Because the creep locking system

is only required for the first day post-

farrowing, a single Split Suckling Aid

unit actually serves around 70 breed-

ing sows in a year, reckons Niels

Veng. Each unit comes with a meter

for setting the magnetic closing and

opening system. A digital display

shows the time remaining before

opening. Battery level is also indi-

cated. If the battery fails, the lock is

automatically released. Charging of

the lithium-ion batteries is normally

required every two months or so,

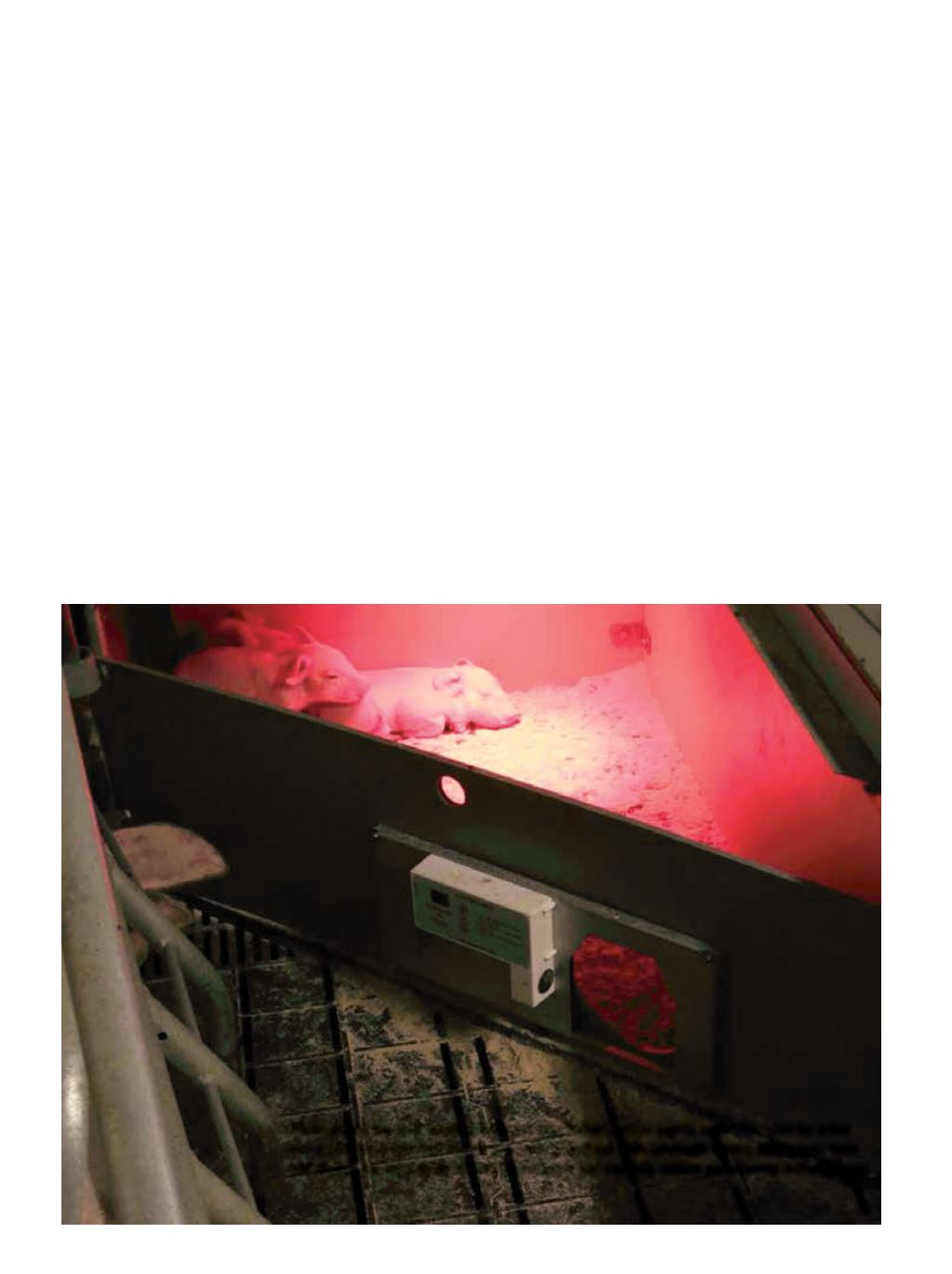

When closed, the Split Suckling Aid creep door keeps heavier piglets under detention for a few

hours after they have had their first drink of colostrum. This automatic system allows later-born

and weaker piglets a better chance at the udder and can help reduce pre-weaning mortality.