Better Farming

January 2017

Dig Deeper:

BetterFarming.com53

MACHINERY

AT

WORK

B

efore you begin to check over

any mechanical front-wheel

drive (MFWD) tractor, make

sure you have something handy on

which to record your findings. These

notes will make it easier for you to

remember any problems or issues and

give you a better picture of your

equipment’s condition.

Start by visually breaking down the

MFWD tractor in sections and

inspect each section of the machine.

Some examples of sections include:

front axle, engine, transmission,

hydraulics, hitch mechanism/drawbar

and cab. And there might be more

sections, depending on how your

machine is equipped.

My recommendation is to have

your grease gun handy. That way, you

proceed at a slower pace and get a

good chance to look around while

greasing the machine.

On a front axle, look at the axle

pivot bushings. These bushings are

crucial to keep the axle in place and

need to be greased regularly.

Lift the front of the tractor until

the axle no longer carries the weight

of the machine. That positioning

allows for a good check on play in

the axle pivot and provides you with

a good opportunity to grease as

well. You can look at wheel bearings

and kingpin bearings at the same

time. When the weight is off of the

wheels they are easy to turn, so you

can check or change the oil in the

drive hubs.

On the engine, check fan drive,

look for play, and see if the viscous

fan is functioning properly. Inspect

the fan belts for wear.

Also examine the alternator and

starter motor wiring. Check the

cooling package for cleanliness and

leaks, as well as all coolant hoses for

wear. Examine the water pump weep

hole – look for signs of oil or coolant

leaks in this hole.

Inspect all fuel lines, filters and

pumps. Most fuel filters have either a

drain valve or a clear bowl to spot

water in the system. Drain any water

and, if a large amount is present,

change your filters and drain water

out of the fuel tank as well.

Pull the dipstick out of the engine.

Do you see any odd discolouring of

the oil (grey or brown), any conden-

sation etc.?

Is the intake and exhaust system

free of any leaks or cracked hoses?

Are the air filters and housing clean?

A good way to inspect an air filter is

by holding a light on the inside of the

filter and trying to look through it.

Can you see dirt or weathered filter

material?

Make sure the inner safety filter is

clean. If this filter is not clean,

something is wrong with your main

filter or the sealing of the filter

housing.

On your transmission, examine at

the filler cap and dipstick. See if the

oil has any discolouration or odd

smells, or if there are signs of conden-

sation on the transmission.

If they are present on your specific

tractor, check cooler lines and shift

linkages. Or, in solenoid-controlled

units, make sure all wiring is in place

and none was damaged during the

season.

Also inspect the drive shaft

between the engine and transmission

if your unit has an external drive

Checking over your MFWD tractor

The winter months are a perfect time to complete maintenance on your equipment. Consider these

practical tips when inspecting your tractor.

by JAAP KROONDIJK

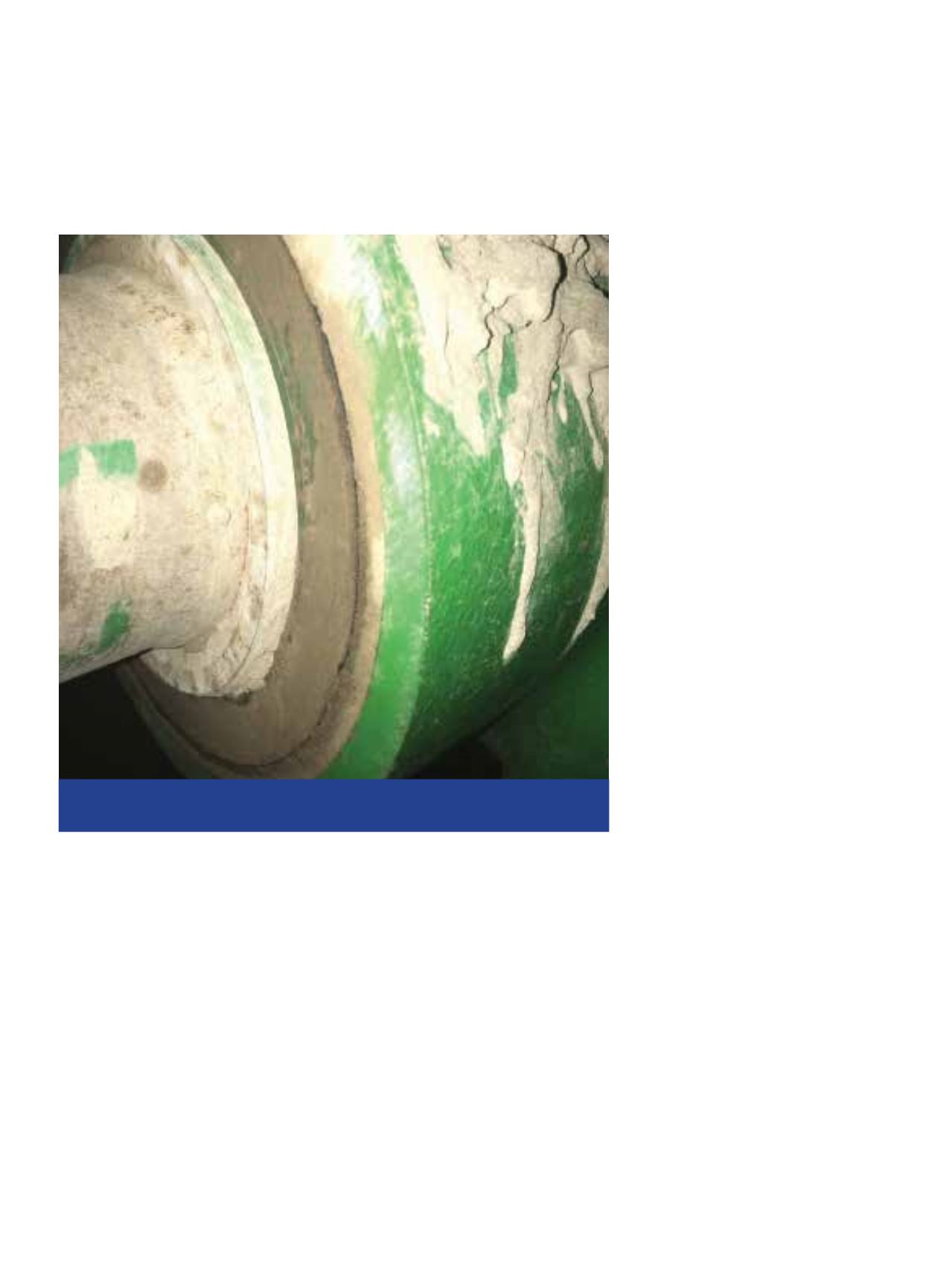

Look for leaks in the rear axle seal and wheel bearing area.

Make sure, too, that there is no play in the axle.