52

Dig Deeper:

BetterFarming.comBetter Farming

January 2017

HOW

IT

WORKS

Niagara Falls. This is often referred to

as “clean” power.

Where are we going?

There is no doubt in my mind that

more and more rural customers will

be looking at ways to go “off-the-

grid.”

In early 1986, I completed a

research report for a joint contract

supported by the Agricultural Energy

Centre of OMAFRA and the Ontario

Ministry of Energy, in cooperation

with the Engineering and Statistical

Research Institute, Research Branch,

Agriculture Canada. The report was

titled “Biogas Production Facilities on

Farms.” We covered all existing

digestion systems in Canada and the

northeastern United States.

At that time electricity generated

by biogas systems was not viable

because utilities like Ontario Hydro

would only pay a very nominal

amount for supplied electricity.

Storing biogas on the farm for

on-demand use was not reliable or

safe.

Only a few biogas-generating units

are in operation in Ontario today.

In Germany, many “free-standing”

biogas-generating systems are

operating very effectively. These

German systems are using significant

additions, including chopped corn

plants and other plant byproducts

such as oat hulls, to the animal waste

that was/has been the primary biogas

input in Ontario.

Where relatively cheap natural gas

is available in Ontario, along with a

consistently high electrical demand,

on-site electrical power generation

can and will become a primary

source of electrical/heat input. Grain

drying systems, ethanol production,

large greenhouse operations, and

large dairy operations are all poten-

tial users of on-site generation.

Unfortunately, specialized knowl-

edge and dedication was, and will be,

required to operate anaerobic

digester systems. For example, an

antibiotic used to treat animals can

kill the desired microbes in the

digester, just as some soaps or other

additives like milk can shut down a

septic system.

Gas-fired systems are simpler and

will become more common as long as

the electrical demand is high and

consistent.

In conclusion

Many smaller commercial users of

electrical energy in Ontario will

continue to shut down their opera-

tions due to high electrical and

labour costs.

I believe the green energy pro-

gram is not and will not fill the need

for reasonably priced electrical

power in Ontario on a 24-hour/365

day basis.

We as small rural users of electri-

cal energy are in a no-win situation.

We cannot afford to buy high-priced

electrical energy with the unreason-

able distribution component.

But going off the grid and gener-

ating one’s own electrical power is

just not a practical solution for most

farmers.

I must come clean at this point.

From 1969 to 1974, I worked for

Ontario Hydro in Toronto as a farm

sales officer, also known as an

agricultural applications engineer.

During that time we promoted the

effective and efficient use of electri-

cal energy on all Ontario farms.

Why? Because there was a need to

increase the flow of electrical energy

into those low-density areas in order

to keep the price per kWh down.

How ironic! As I stated in my August

article, the peak system demand was

always on the Monday preceding

Christmas day.

The tremendous increase in load,

primarily by air conditioners, has

moved that peak system demand

into the hot summer days.

I ask: should we in the rural area

supplying food be penalized for

using electrical energy efficiently for

the benefit of all Ontarians?

BF

Ralph Winfield is a retired professional

engineer, farmer and technical writer.

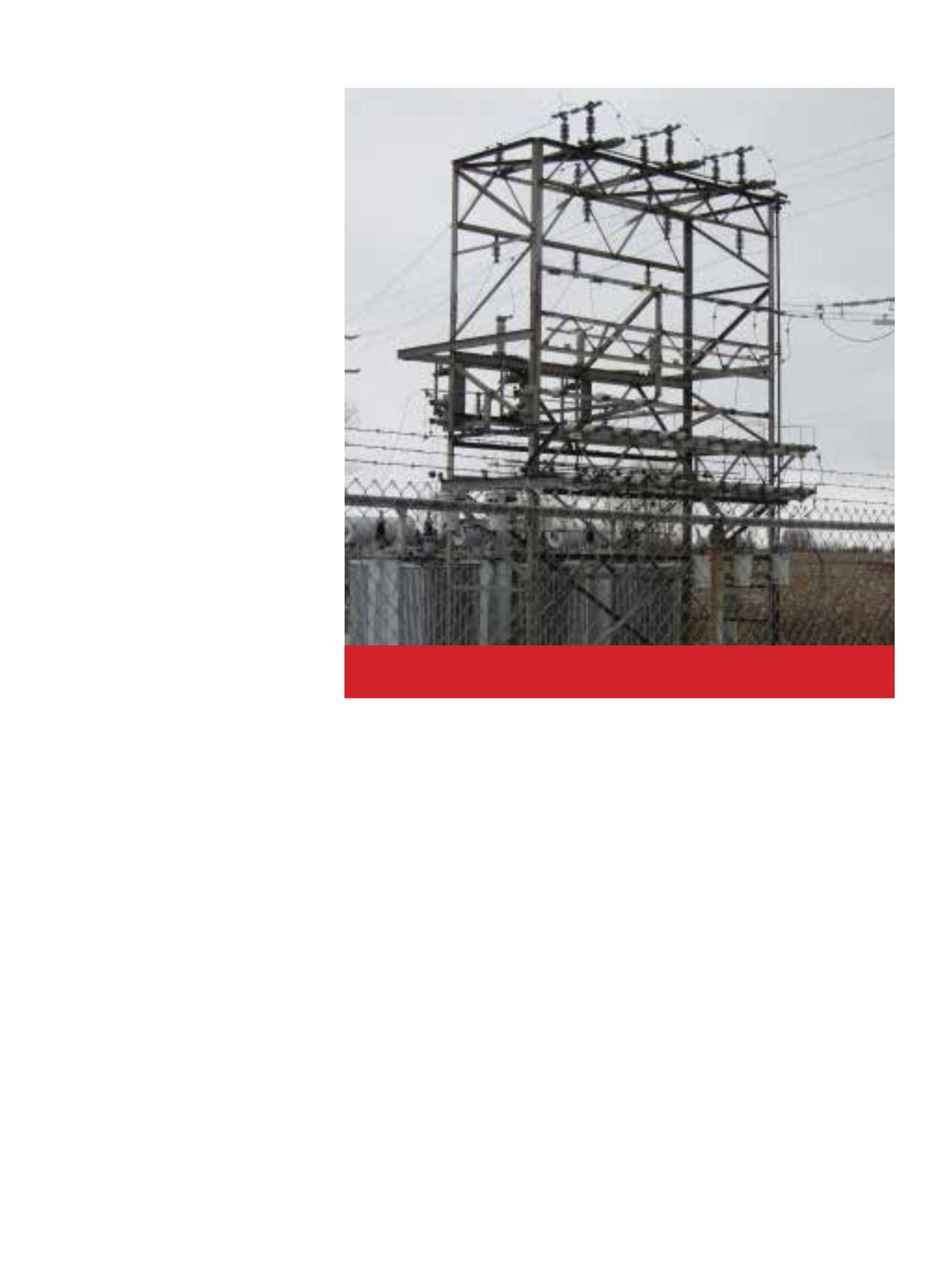

A local hydro distribution station reduces the voltage down from

27.6 kV to distribution voltage.