22

Like Us on Facebook:

BetterFarmingON

Better Farming

December 2016

RISING

ELECTRICAL

COSTS

commercial elevators. The “dryera-

tion” process developed at Purdue

University was among the first to be

field tested in Ontario.

Hot dried corn was removed from

the dryer when the moisture content

(mc) measured between 16 and 18

per cent. Then the corn filled one of

three tempering bins, usually con-

crete silos. The grain sat for about

eight hours before a relatively large

fan output of 0.5 cubic feet per

minute (cfm) per bushel was blown

up through the corn to remove the

two-to-three points of moisture and

cool the grain. That corn then had to

be moved to another dry bin so the

tempering bin could be reused.

Dryeration provided a high-quality

output but required careful monitor-

ing and an additional handling of the

corn at a very busy period. New

continuous flow dryers with a

tempering section between the drying

and cooling sections basically took

over.

As fuel costs continued to rise, the

concept of reclaiming the heat from

the cooling section became popular

and was very effective. However, the

red dog released from the dry corn

could be passed directly into the

drying section through the burner.

This fire hazard had to be eliminated

by providing a settling chamber for

the red dog. The collected red dog

could be taken to the field in a

manure spreader, which eliminated

the product from the drying area.

The next major progression was

the introduction of screen-less dryers.

They solved two major issues. Previ-

ously, corn over-dried when it flowed

along the hot inside dryer screens.

This process resulted in broken

kernels and excessive unsaleable fines.

Screen-less dryers solved these

problems.

These screen-less dryers operated

on a batch drop system. The airflow

was stopped temporarily, and the red

dog could be collected and diverted

to a special bin for disposal.

Handling changes

It was often very difficult to convince

a person who was planning to build a

first drying system to (a) move the

system away from the old livestock

buildings on the site and (b) make

provisions for the eventual inclusion

of a leg elevator.

I still recommend both. Virtually

every drying setup now has a large

dump pit and at least one high-capac-

ity leg elevator.

High-rate grain-handling capabili-

ty is an absolute must to eliminate the

pesky elevator lineups that plagued so

many of us in days gone by!

In addition, that high-capacity leg

elevator can also greatly reduce

load-out times for the grain trains

moving dry product outbound.

One final thought

Would you have ever visualized a

200-hp motor on a leg elevator? They

do exist and not just on the high-ca-

pacity elevators used to load and

unload ships!

BF

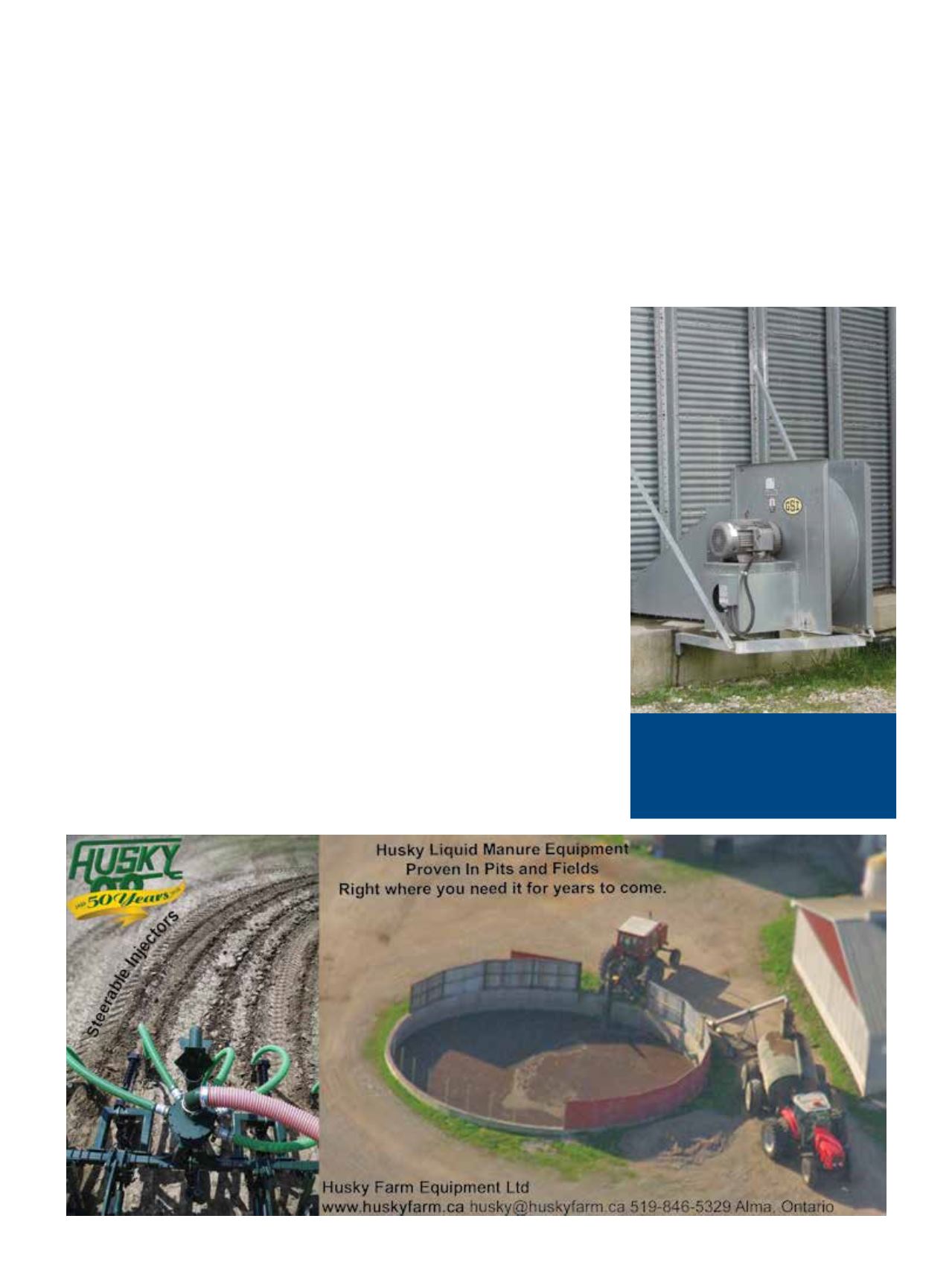

New large-diameter (high-

capacity) grain bins require four

20-hp fans just for aeration to

maintain the desired grain

temperature.