Better Farming

December 2016

Follow us onTwitter

@BetterFarmingON

21

RISING

ELECTRICAL

COSTS

kilowatts (kW). Thus other activities could also be

accomplished without incurring a demand charge.

Aeration fan motors on those small bins were usually not

more than two hp. If the electrical demand exceeded 50

kW, charges would only be applied for one month, as the

meter reader reset the demand indicator during the

regular monthly visit.

If on-farm drying systems did expand to effectively

become commercial drying systems, three-phase power

was a must. The drying system could be strategically locat-

ed adjacent to a three-phase line or, with a capital contri-

bution, three-phase lines could be extended to the desired

farm site.

The cost of hydro

Up to the early 2000s, electrical energy was relatively

cheap, and many relatively large on-farm drying systems

appeared in Ontario. By 2010, the cost of extending

three-phase service and the cost of electrical energy in

Ontario increased significantly.

The option of generating electrical energy with natural

gas as the engine/generator fuel needed consideration.

One of the largest installations that I am aware of is in

western Ontario. When a high-capacity screen-less type

dryer was installed in 2009, a dedicated large V-12 natural

gas engine which produced about 870 hp and powered a

600-kVA (kilovolt amp or about 500 kW) generator, was

attached. This combination system directly provided all of

the electrical energy for that large screen-less dryer. All of

the engine waste heat, as well as the exhaust gases, was

directed into the air stream to the grain dryer to maximize

energy efficiency.

This concept is not unique. As hydro rates continue to

increase, along with the high delivery charges, many

potential on-farm dryer operators are being encouraged

by equipment suppliers to consider this type of combina-

tion system. However, many of these systems would be

much smaller and could be wired/controlled so that the

power system could also be used as a standby power

system for the entire farm in the event of an outage or for

use during the on-peak billing times.

It is important to note that these power systems cannot

be used to feed the power grid. They would need to be

synchronized and do not meet the requirements of

Ontario’s Green Energy Act. However, gas-fired electrical

generation systems have been used for many decades as

“peaking plants” by electrical power suppliers in Ontario

and elsewhere.

Grain drying and handling progression

In the 50 years that I have been involved in grain drying

in Ontario, many changes have occurred. As I noted

earlier, the first on-farm grain drying appeared to help

farmers avoid those persistent lineups at the local small

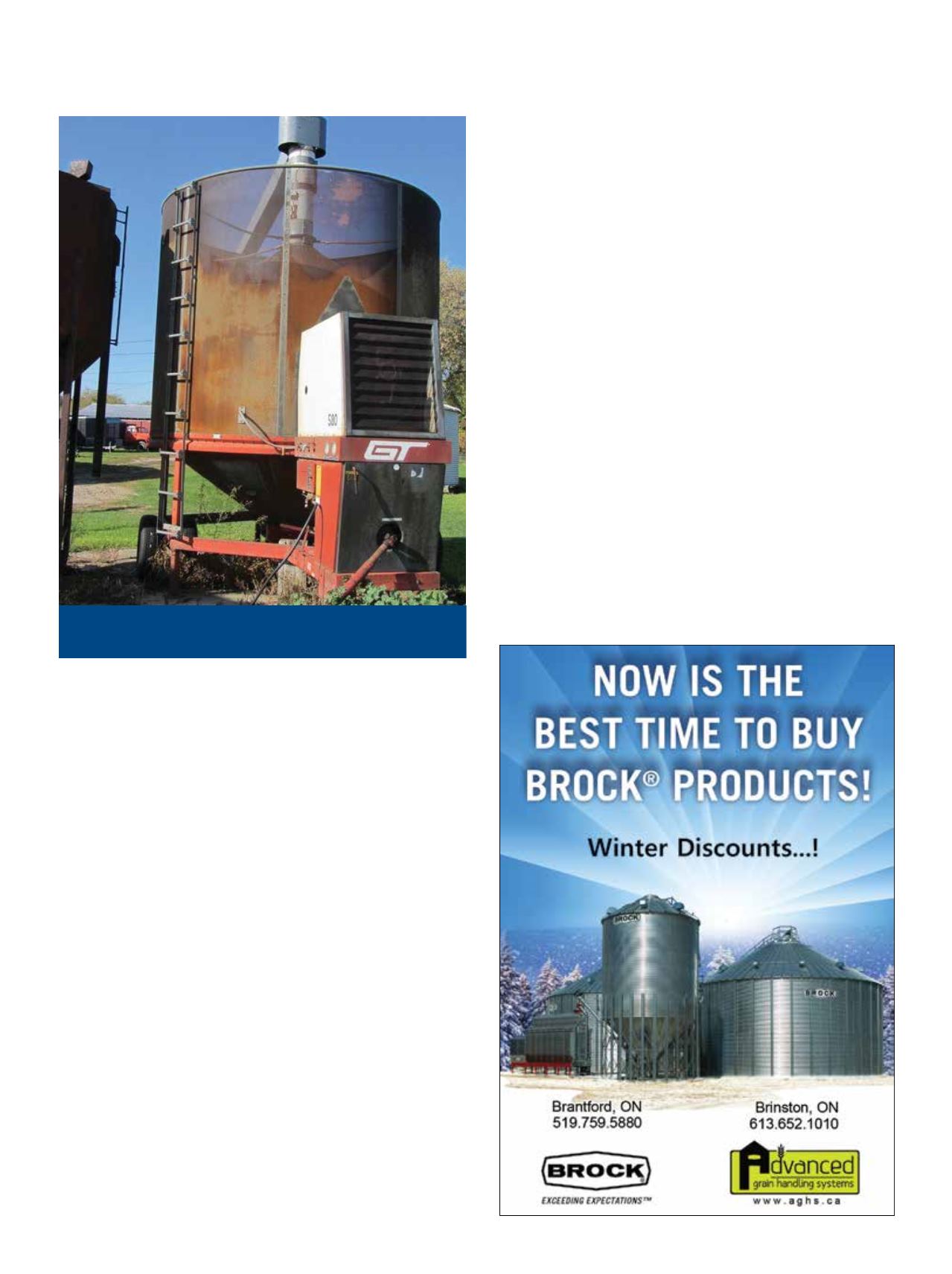

This older batch-type dryer that is PTO-powered

by a tractor is still in use.