Better Farming

September 2016

Farm News First >

BetterFarming.com27

approaches. Because of this detail,

“we can put a tractor on the same

pattern every year. The tractor is driv-

ing over the same spot, year after

year.” Sticking to the same patterns so

precisely reduces soil compaction,

boosts yield and promotes overall soil

health, he says. “It allows you to apply

bands of fertilizer in a given area for

precise application.”

The potential for guiding and

operating agricultural equipment in

the future is immense.

“In the automotive industry, we’re

already seeing automatic parking and

vehicle-assisted braking. This tech-

nology will transfer to the agricultur-

al space,” says Bose.

Bose envisions the day when

driverless planters will do variable

seeding. Farmers would control the

planters remotely using a tablet and a

pre-programmed pattern based on

historic yield data.

Data helps boost yields

Even right now, however, the technol-

ogy is making a fundamental and

beneficial impact to farmers’ bottom

lines.

“At a recent presentation I made, a

farmer came up to me after and said

the variable rate seeded everything,”

recalled Redmond. “The difference on

corn – which is what everyone is

talking about – was about $9 an acre.

Big deal. But on some specialty crops,

like edible beans, the difference in

yield was $36 an acre. This guy had a

thousand acres of edible beans.”

Don’t dismiss the impact on corn

too quickly, though. DuPont Pio-

neer’s research and development

people have done the tests and run

the numbers. Comparisons of

variable rate seeding versus constant

seeding at 556 locations across North

America have shown increased corn

yields of between eight and 13

bushels an acre.

Yield information can also give

direction on decisions like hybrid

selection, chemical application,

planting density and more.

“It used to be that we’d have one

or two hybrids on a farm,” says Blaine

Calkins, Encirca Services manager at

DuPont Pioneer in Johnston, Iowa.

“Now, we are talking potentially

multiple hybrids within one field.”

Combining multiple hybrids with

variable rate planting will boost plot

productivity, he adds.

continued on page 30

have two or three years or more of

yield data. It’s valuable information.

The more you understand about

tracking yields, the better. Ten years

from now, we may find a missing

piece in that data if we can extract

information from it.”

The volume and the different types

of information that can be collected

can be overwhelming to a typical

farmer. For that reason, you need to

surround yourself with trusted

advisors, Redmond advises.

“You’re dead in the water if you

don’t,” he says. “When we first started,

we’d find farmers who didn’t know

how to work their yield monitor

properly. These were guys with

Masters and PhD level education, and

they wanted to do it all. But they have

to build support relationships with

the equipment dealer, software

representative and agronomist.”

Information overload

The downside to all that data collec-

tion, however, is its sheer volume,

Calkins says. “There’s so much data

(that) farmers out there probably

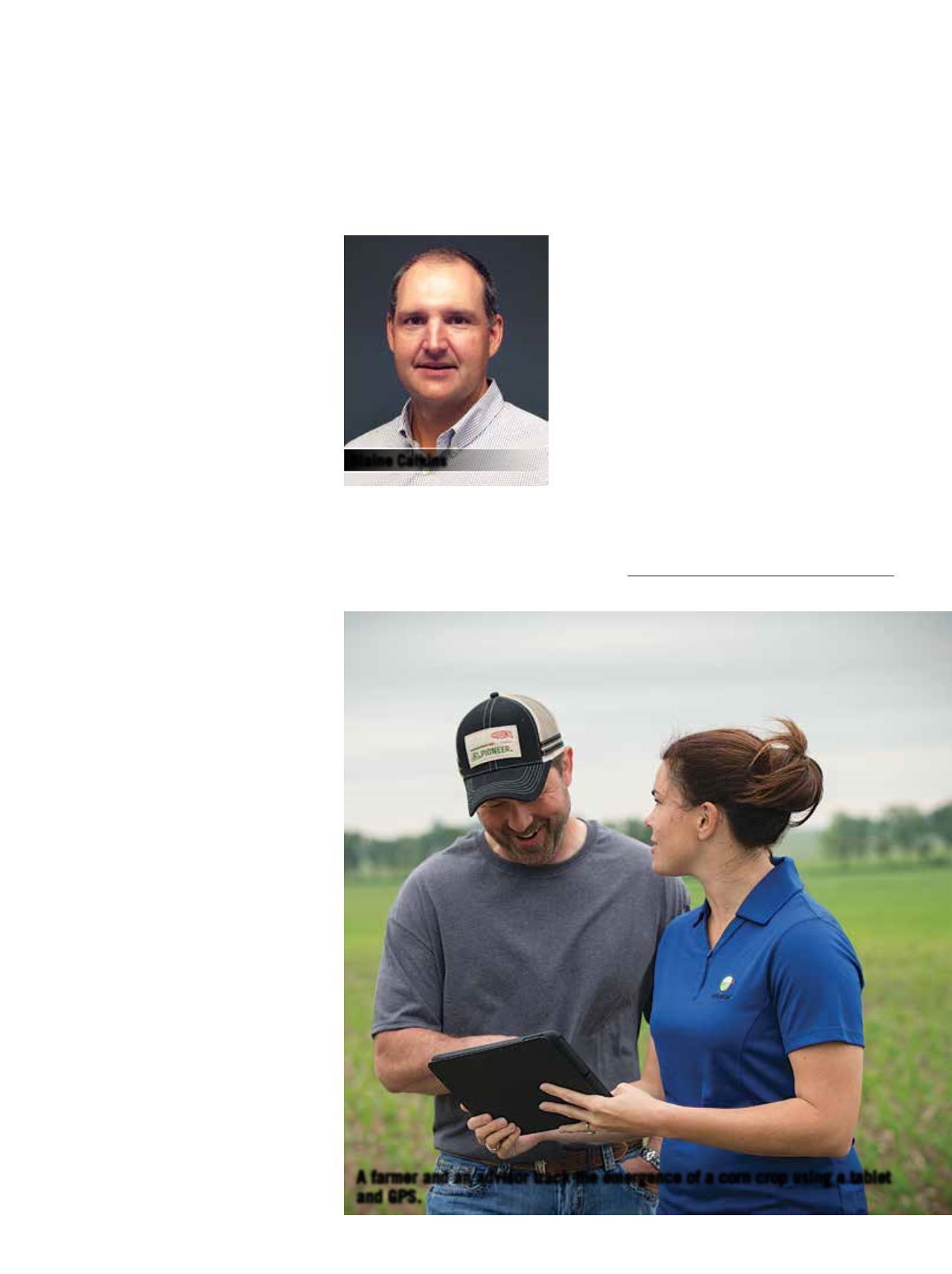

A farmer and an advisor track the emergence of a corn crop using a tablet

and GPS.

Blaine Calkins

Photo: Courtesy DuPont Pioneer

PRECISION

AG