54

FarmNews First >

BetterFarming.comBetter Farming

November 2016

MACHINERY

AT

WORK

the front axle and the corresponding 60 to 70 per cent on

the back axle. The 30/70 split is increasingly becoming the

norm, especially for a tractor that has to use its own

weight to pull.

One such example would be a cultivator that does not

transfer any weight onto the tractor pulling it. While

pulling the cultivator, the tractor is overloaded on the

front as opposed to the back, and will likely go in power

hop mode. And power hop puts the tractor into an uncon-

trollable state of bouncing. In severe cases, the tractor

even breaks free from ground contact. If you have never

experienced power hop, talk to someone who has - it is

an unnerving experience. You lose all control and end up

going nowhere. You waste a whole lot of time and money,

spinning your tires and wasting fuel.

On a MFWD tractor, the front axle runs faster than the

back axle. The different axle speeds are needed to account

for the different tire sizes so that the back tires will not

push over the front tires. So the front will always need to

be able to “slip” to get rid of the extra ground speed it

runs.

Overloading the front of the tractor causes the front to

pull too much and it will try to drag the back along. At a

certain point, the front tires are inevitably going to break

free from ground contact and possibly cause power hop or

a mechanical failure somewhere in the drive line.

For average duty pulling, you need approximately 120 lbs.

of weight per unit of horsepower. A 200 hp tractor, for

example, would need approximately 24,000 lbs. total

weight with approximately 7,200 lbs. on the front and

16,800 lbs. on the back.

A lot of tractors are built in such a way that the front is

likely heavier than the recommended weight, while the

rear is a lot lighter than recommended. So, putting a set of

front weights on the tractor makes it look impressive, but

does not improve performance. In fact, the addition of

this weight on the front might hinder your performance

with some unfavourable side effects - like power hop.

On several occasions, I have suggested that farmers

remove their front weights or hang them on the back.

Those who took this advice were pleasantly surprised.

Unless you need those weights on the front for lifting a

heavy three-point implement, don’t hang them on the

tractor until you have the rear of the tractor properly

weighed down with a set of wheel weights or a ballast

weight hanging on the quick hitch. The latter type of

weight gives you the flexibility to remove it quickly if

necessary.

If you are using an implement that will transfer weight

to your tractor, you will need to account for that weight in

your calculations. And, as noted in the October edition of

Better Farming

, remember to adjust your tire pressure so it

will carry the weight properly but still allow enough flex

in your radial tires for proper weight distribution and

traction.

When in doubt, ask your tire supplier to provide small

portable weigh scales so you have accurate weight and

pressure recommendations directly from the experts.

BF

Jaap Kroondijk is a farm boy mechanic who lives near

Woodstock.

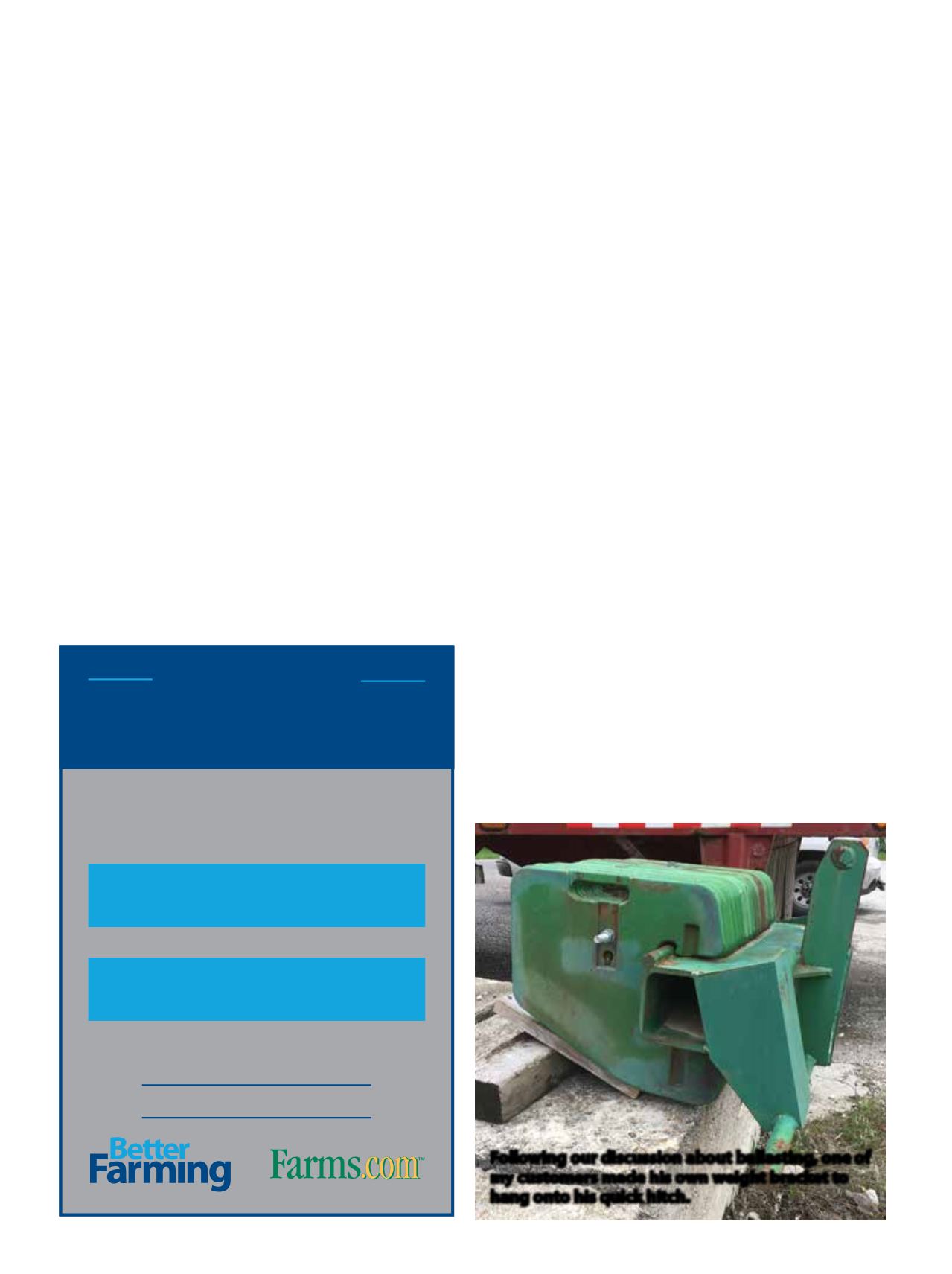

Following our discussion about ballasting, one of

my customers made his own weight bracket to

hang onto his quick hitch.

Better Farming , Ontario’s top agricultural publication, and Farms.com are hiring exceptional talent for 2 positions. (ENTRY LEVEL POSITION) Apply online on AgCareers.com and enter the job ID number. DEADLINE: NOVEMBER 7, 2016 Inside Sales & Lead Generation #565565 CAREER OPPORTUNITY Join Our Team Sales & Business Development #565564