Better Farming

November 2016

FarmNews First >

BetterFarming.com21

FIELD

TRIP

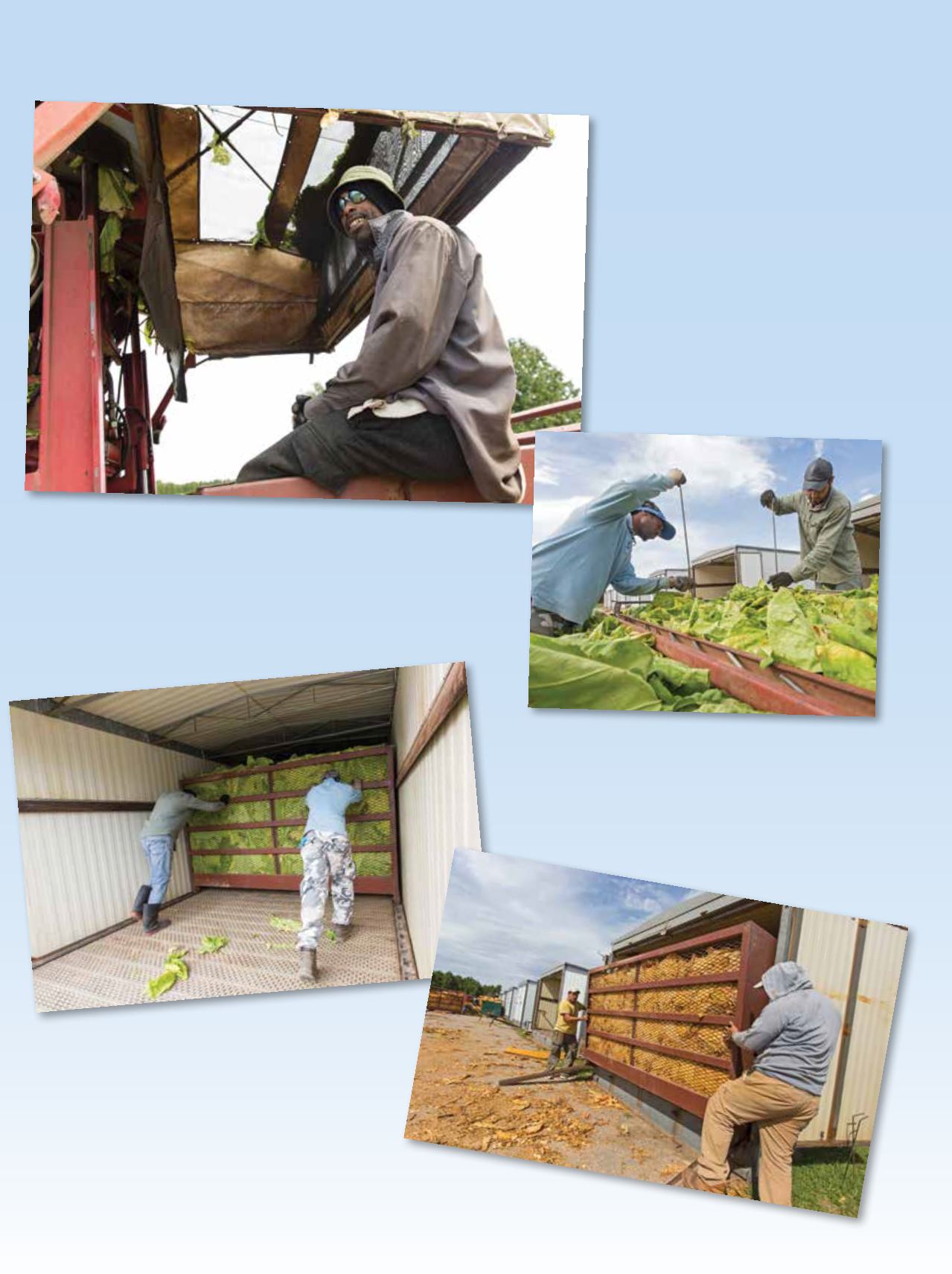

Phil Edmund takes a break while waiting

for an empty curing bin to be delivered

to the harvester in the field. Edmund is

part of a two-man harvester crew, working

with a driver. Edmund’s job is to stand

on an upper level and direct cut leaves so

they evenly fill the bin as the harvester

drives along the rows.

Terry Leatham (left) and Carlos Run place separating pins into a

curing bin full of freshly picked tobacco brought back from the

harvester. These separating pins promote airflow and prevent

spoilage by keeping leaves separated when the bin is tilted

vertically for loading into the kiln.

Omar Sosa-Castillo (left) and his brother

Alejandro remove a bin of cured and dried

yellow leaves in preparation for sorting and

baling.

The curing bin of fresh tobacco is then slid up a short

ramp and into a kiln where it will rest for thirteen days.

Curing starts at 32 C and final drying temperatures

reach 66 C.