Better Farming

October 2016

Farm News First >

BetterFarming.com55

MACHINERY

AT

WORK

All radial tire manufacturers have

tire guides, and most equipment

manufacturers have this information

in their operator’s manuals as well.

The tire guide will show you what

your tire size is capable of doing, and

what weight it can carry at what

pressure and at what speed. Better

tire guides will give you two or more

tire pressures for the same weight.

These pressures depend on what

speed you travel. A substantially

higher pressure is needed to prevent

too much flexing of the tire at higher

speeds. At a lower speed, in contrast,

not as much heat will be generated

and a lower pressure will suffice for

carrying the weight. If you do a lot of

hauling of weight (like spreading

manure), you would want to use the

higher pressure scale for the weight.

This way, you will not do damage to

your tire by traveling at higher

speeds.

But this means you need to do

some homework and know the

weight of the equipment (and any

loads) on the tire. In cases where the

weight can vary (like the rear axle of

your tractor, depending on the

implement hooked up), you might

need to know multiple equipment

weights and the necessary

corresponding tire pressures. Take the

time to set the tire pressure right!

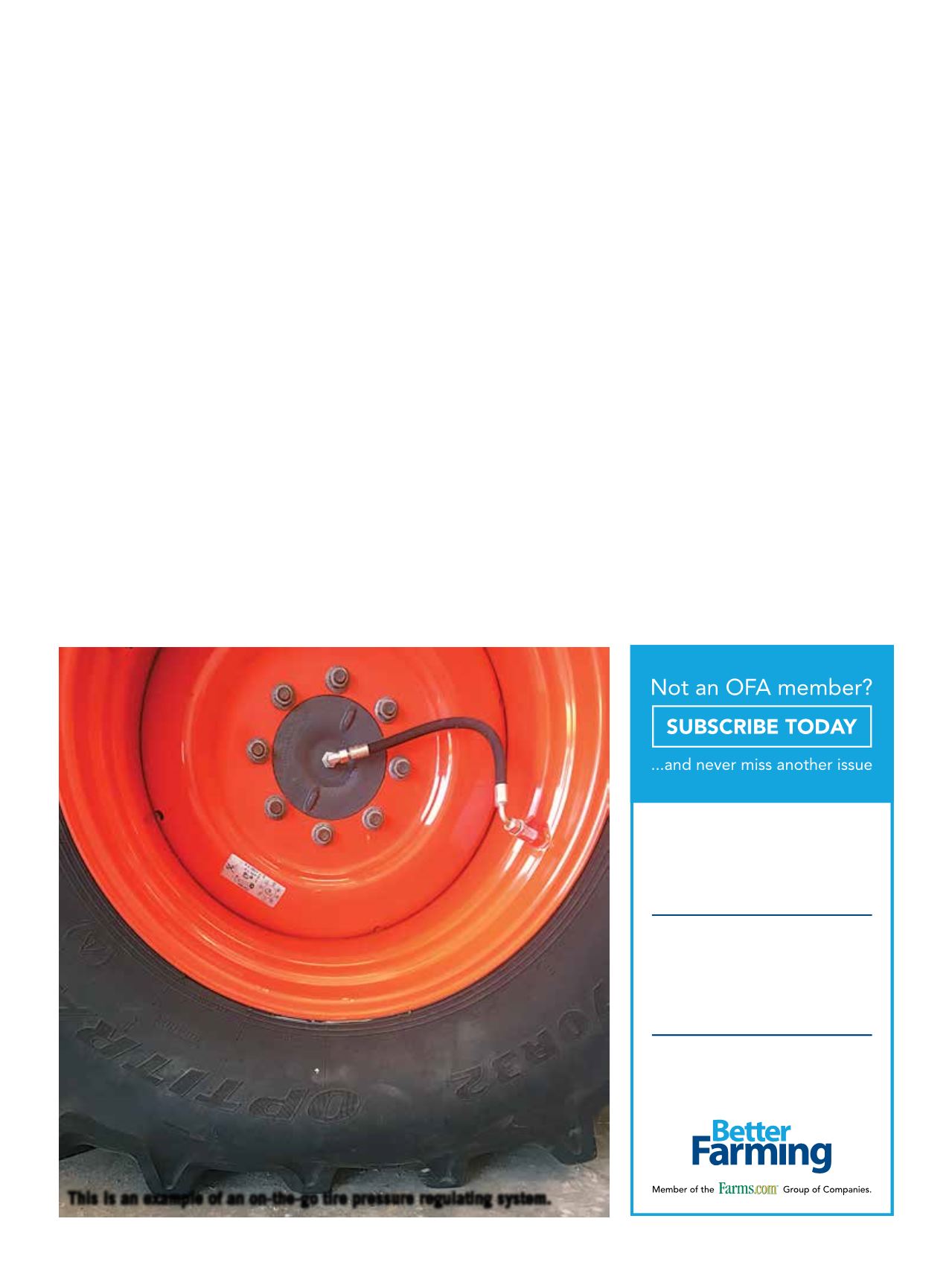

The use of an on-the-go tire

pressure regulating system is another

option.

You might think that this process

sounds like a lot of work and one

pressure will do for all of your farm

and field work. Well, let me give you

something to think about. While

working as a technician I was ap-

proached by one of our sales associ-

ates. He needed to demonstrate a

tractor against a competitive brand

tractor with a higher horse power. We

did not have the equivalently rated

HP in stock and had to go with a

tractor with 30 HP less. This was not

an ideal situation and was a cause for

anxiety on the sales side. We ballasted

our tractor the best we could and set

the tire pressures accordingly. We ran

circles around the competition

pulling the same implements.

How, do you ask? Well, we put

traction to the ground and pulled.

The tires on the competitor’s tractor

still had high tire pressure from

shipping. (This high pressure allows

for a more solid tie down on the

truck so the load is more secure.) The

competitor’s representative did not

adjust the tire pressure for the

fieldwork, and consequently the

tractor did a lot of tire spinning –

even though it had lots of HP on-

board. We sold our tractor while the

competition, who had been sure of an

easy sale, had to take its tractor home

again!

Moral of the story: know your tire

pressures and set them right.

Proper tire pressure saves fuel and

saves your soil. Both are money in

your pocket in the long run.

BF

Jaap Kroondijk is a farm boy mechanic who

lives near Woodstock.

This is an example of an on-the-go tire pressure regulating system.

Better Farming readers receive the top insight on Ontario ag in each and every issue. We’re the trusted source for commercial farmers. A $41 ONE-YEAR SUBSCRIPTION IS A 44% DISCOUNT ON NEWSSTAND PRICES. CALL 1-888-248-4893 EXT. 255