Better Farming

December 2016

Dig Deeper:

BetterFarming.com53

MACHINERY

AT

WORK

Determining winter maintenance plans

Use the winter months to complete oil changes and decide which repairs should be undertaken to

prepare your equipment for the coming season.

by JAAP KROONDIJK

A

ccording to Wikipedia,

“technical maintenance is

intended to maintain or

improve the health of some asset. It

forms an integral part of any asset

health management strategy.”

Your equipment is part of your

farm business assets, so put the

statement above into practice and

maintain your equipment. Mainte-

nance is a management decision.

Consider: what do I expect from

that piece of equipment next season

and how many more seasons do I

need to use it? With those questions

in mind, you need to give your

equipment an honest going over

before putting it away for the winter.

Believe me – all the issues it has today

will still be there next spring. And the

problems will likely get worse if you

don’t address them sooner rather

than later!

Keep a notepad, iPad, you-name-it

pad handy and start by making notes

about what is not working properly

when you use your equipment. You

or your operator know best what

issues have slowly developed. And, if

you do not complete your own

maintenance and repairs, then share

that information with your techni-

cians. Having this information saves

them a lot of time and helps to

prevent them from overlooking the

item that annoys you the most.

The owner’s manual for most

pieces of equipment typically has a

maintenance schedule which states

the recommended oil and filter

interval changes. The schedule also

outlines other factory-recommended

maintenance items. These recom-

mendations are based on regular use

of the equipment, which is not the

case with a lot of seasonal machinery.

For example, if you put 200 hours

a year on a piece of machinery and

the engine oil interval is 500 hours,

then do not wait two and a half years

before changing the engine oil! Yes,

technically, this is what the mainte-

nance schedule directs, but that is not

a wise move.

Oil breaks down and, in the case of

engine oil, it should be changed at

least once a year. If you run 1,000

hours per year, then an oil change

twice per year would be acceptable.

The same rule applies for hydraulic/

transmission oil – do not wait longer

than two years to complete this type

of oil change or you will be in trouble.

Use sound judgement when

making your oil change decisions.

Consider: what do I expect of my

machine and how do I use it? Better

10 oil changes too many than one

short; oil and filters are cheap com-

pared to the investments you made in

the purchase of your equipment or

the untimely expensive repairs

completed by your dealer due to lack

of proper maintenance.

Considering the hourly door rates

at your dealer, it should not take a

calculator to figure out that routine

maintenance and some parts will save

you money in the long run.

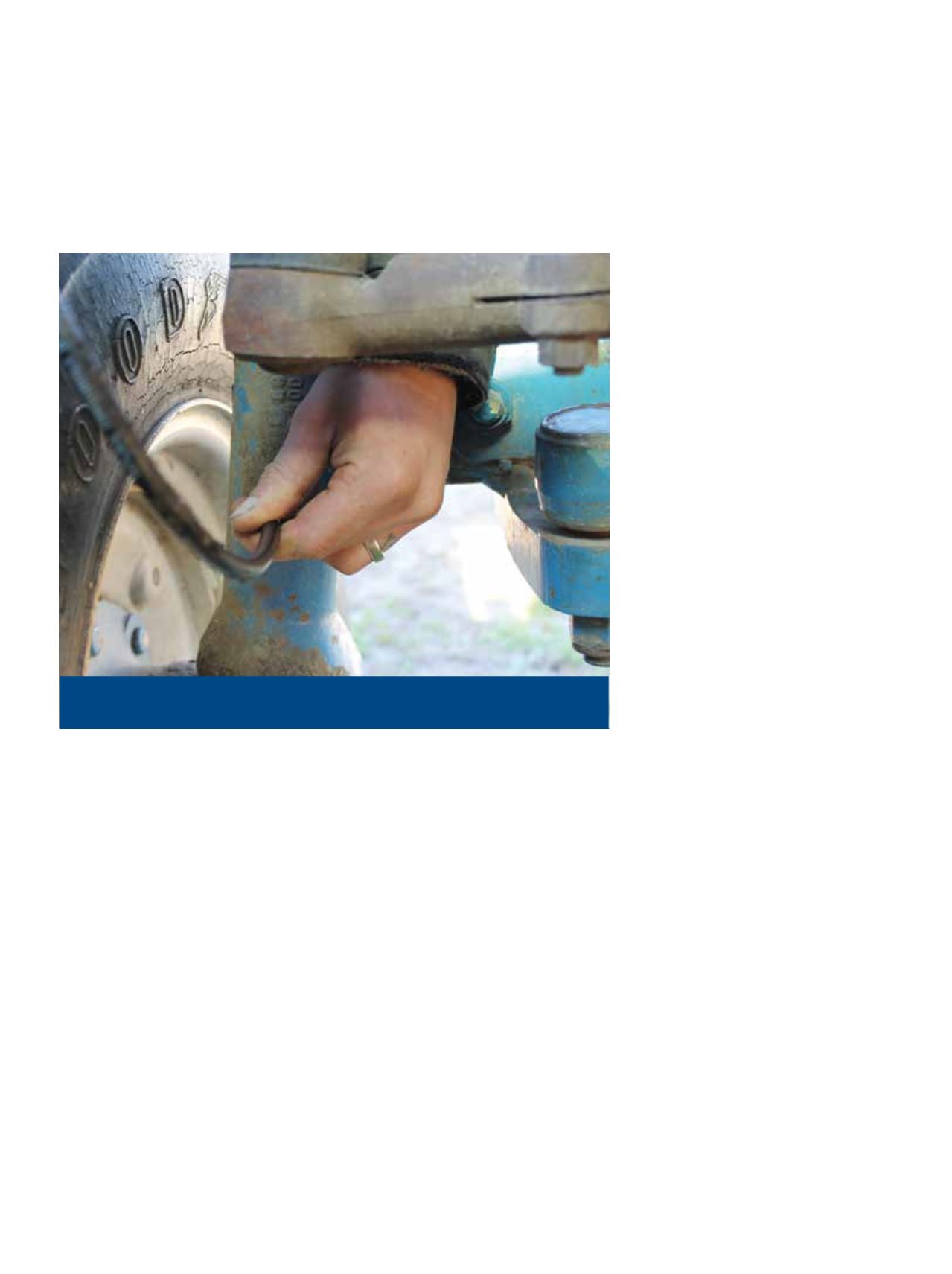

If you do your own work, then

start with the notes you made during

the season. Grab the grease gun and

start systematically and intentionally

going around the machine. Look for

leaks, worn or damaged parts and

grease the machine at the same time.

Mark down what you see and survey

the whole machine! Only then can

you make a sound management

decision on what course of action to

take with this particular piece of your

assets.

Once you thoroughly examined

the machine, you have a good picture

of its condition and what it needs to

serve you for another year. Or,

perhaps a decision to replace the unit

Grab the grease gun and start systematically and

intentionally going around the machine.