Better Pork

February 2017

35

NUTRITION

were from the same corn source and

had identical particle sizes, it is pos-

sible that the pelleting process may

have negatively impacted the particle

size of the diet. Achieving a finer

grind would explain why stomach

morphology scores worsened when

pigs were fed pellets.

The researchers suggested that an

increase in fluidity of the stomach

contents could have led to increased

incidences of ulceration. References

in the literature show that the pH of

the stomach is more consistent in

all four regions when pigs are fed a

pelleted diet compared with a coarse

meal diet. These findings could indi-

cate that the level of fluidity creates

an environment where there is in-

creased mixing of stomach contents

when a pelleted diet is fed.

The researchers also performed

an economic analysis of the research

outcomes (data not shown). For the

purposes of this analysis, pig remov-

als during the trial were considered

mortalities. The economic picture

showed that feeding a meal diet

throughout the experiment signifi-

cantly increased feed cost ($/lb gain)

compared to all other treatments.

There were no significant dif-

ferences in income over feed cost

(IOFC; calculated as total revenue/

pig minus feed cost/pig). However,

there were numerical differences

suggesting that rotating between pel-

lets and meal diets improved IOFC

by $1 to $2 above feeding a meal diet

throughout the finishing period.

In conclusion, these results sug-

gest that rotating between a meal

diet and a pelleted diet during the

finishing period can have an impact

on pig health. This feeding approach

can decrease the incidence of stom-

ach ulcers, while still realizing some

of the feed efficiency benefits of

pelleting. Alternating between pel-

lets and a meal diet also appeared to

maximize economic returns.

BP

Janice Murphy lives in P.E.I. She is a

graduate of the University of Guelph

with a MSc in swine nutrition and has

worked in both the private and public

sectors.

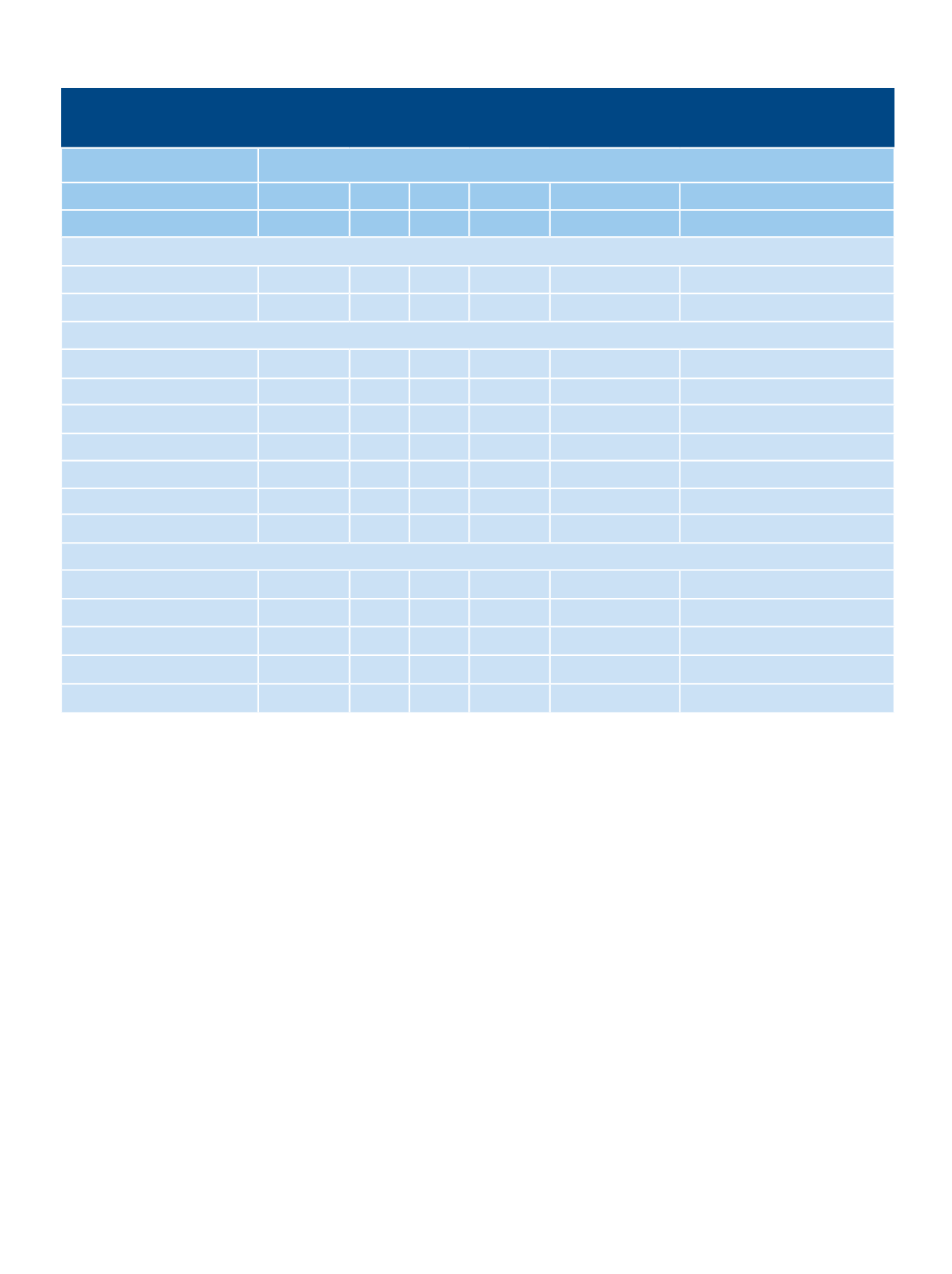

The effect of pellet feeding on finishing pig growth performance, carcass characteristics and stomach

morphology

Period

Diet form fed during period

Day 0 to 70

Meal

Pellet

Meal

Pellet

Rotated

1

Rotated

2

Day 70 to 118

Meal

Pellet

Pellet

Meal

Rotated

Rotated

BW, kg

Day 0

31.5

31.6

31.4

31.4

31.6

31.5

Final weight

135.6

136.6

136.0

134.0

135.3

136.2

Day 0 to 118

Average daily gain, kg

0.96

0.97

0.96

0.96

0.96

0.97

Average daily feed intake, kg

2.36

a

2.26

b

2.30

bc

2.28

bc

2.30

b

2.29

bc

Gain: Feed

0.407

c

0.430

a

0.421

b

0.422

b

0.420

b

0.423

b

Pigs removed/pen

0.50

b

1.92

a

1.06

b

0.93

b

0.85

b

0.92

b

Keratinization score

2.3

2.4

2.2

2.1

2.8

2.1

Ulceration score

1.5

2.0

2.2

1.6

1.8

1.6

Ulcer index

3

5.25

ab

6.72

a

6.72

a

4.61

b

6.15

ab

5.32

ab

Carcass characteristics

Hot carcass weight, kg

97.9

99.2

98.6

97.9

98.4

98.9

Yield, %

74.8

75.2

74.7

74.8

75.3

75.6

Backfat, mm

16.7

17.1

16.8

16.5

16.8

16.8

Loin depth, mm

72.8

73.8

73.9

73.4

73.7

73.9

Lean, %

56.3

56.2

56.2

56.5

56.5

56.3

a–c Superscripts within a row are different (P < 0.05).

1 Meal and pellet were rotated every two weeks starting with meal and ending with pellet. Pigs were fed a meal diet for 10 days prior to collecting stomach morphology scores.

2 Meal and pellet were rotated every two weeks starting with pellet and ending with meal. Pigs were fed a pelleted diet for 10 days prior to collecting stomach morphology scores.

3 An index of stomach morphology was developed by adding a pig’s ulcer and keratinization score. An additional score of four was added to each pig that had an ulceration score greater than one.

Sources: J.A. De Jong, J.M. DeRouchey, M.D. Tokach, S.S. Dritz, R.D. Goodband, J.C. Woodworth, and M.W. Allerson. 2016. “Evaluating pellet and meal feeding regimens on finishing pig performance, stomach

morphology, and carcass characteristics.” J Anim Sci 94(11):4781-4788; and JA De Jong, JM DeRouchey, MD Tokach, SS Dritz, RD Goodband, and MW Allerson. 2015. “Evaluating pellet and meal feeding regimens on

finishing pig performance, stomach morphology, carcass characteristics, and economics.” Kansas Agricultural Experiment Station Research Reports 1(7): Article 18.